Introduction

Labour (or workload) profiling is a useful tool that can be used to assist in the effective management of a facility.

Two types of information are needed to complete a profile.

- The estimated time it typically takes to carry out a task, and

- An estimate of how many times the task will be needed over a year to ensure the desired standards are achieved.

Typical times will vary from one operator to another, for example, especially where ride-on or pedestrian machines are being used. The time may include how long it takes to clean off a machine as well as resetting it for the next time it is used.

This needs to be carefully considered if a comparison is to be made with a similar facility.

The make-up of the times will depend upon individual requirements, however, it is important to try and provide an overall picture that is fairly comprehensive otherwise the maximum benefit will not be gained from this management tool.

The estimated number of times a task is needed will depend upon the overall quality required, usage levels and patterns of use, as well as the prevailing weather. With past diary records a fairly accurate summary can usually be achieved, however, with the vagaries of the weather the anticipated monthly figure will no doubt vary from the planned estimate.

The important point to remember is that this tool is only an aid for forecasting workload and should be adjusted as the year progresses to reflect changes in the weather, as well as the quality of the playing surface produced. More or less work may be needed than was originally anticipated: This is to be expected.

This tool should be used as a working document that is continually updated. Experienced groundstaff will be able to forecast to a high level of accuracy.

By planning ahead a number of benefits can be achieved:

- bottle necks in workload (work 'Peaks') can be immediately identified,

- action can be taken to reduce or eliminate these 'Peaks',

- seasonal / contract staff may be employed,

- work may be rescheduled for other times,

- holidays can be planned to minimise impact on the maintenance work (ideally taking some of these when there are work 'Troughs'),

- staff costs can be more accurately budgeted for,

- cash flow can also be determined.

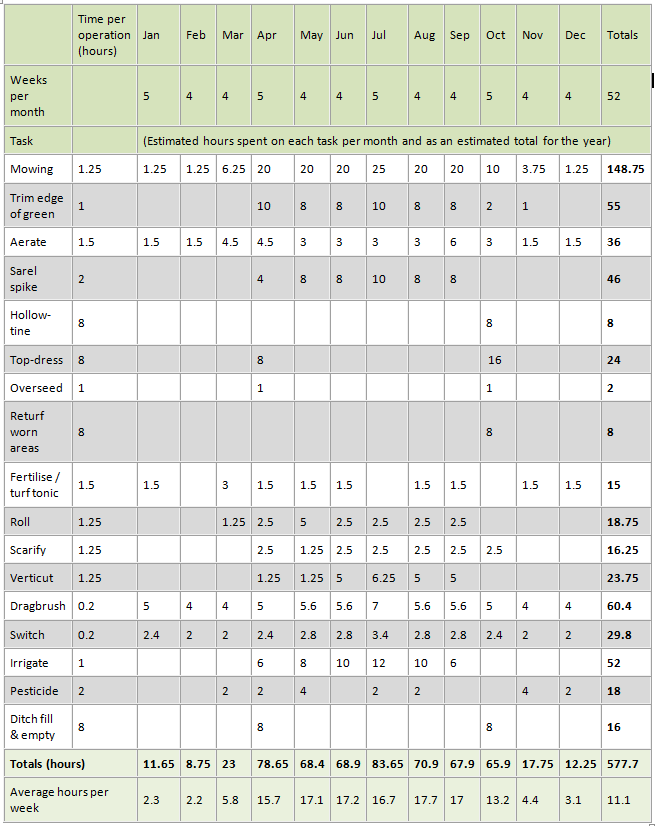

If we look at an example maintenance for a bowling green we can plot in the relevant estimates.

(Please note that the estimated times are only used to illustrate how labour profiling works. Groundstaff will need to put in their own particular figure. However, many of the times given will be fairly representative of a typical time to undertake the stated task on a bowling green).

Download a word version so you can edit it to suit your own requirements

Some tasks such as:

- Rolling may be much less than this, with the only rolling carried out being that of the rear roller from the cylinder mower.

- Drag-brushing and switching can be notoriously difficult to estimate and the figures quoted here would most likely be significantly less in practice.

Other tasks may include setting out the rinks, score boards etc. each morning and would need to be included within the overall maintenance costs.

If a nominal figure of £10 per hour is allowed for staff costs, then it can be readily seen that with the operations detailed in the table, the staff costs of maintaining this bowling green is in the region of at least £5,800.

Add to this some general material costs of £2,400 per annum and a maintenance figure of £8,200 is now arrived at.

Additional figures would be needed for the cost of machinery and equipment and the relevant repayment costs, or whatever financing costs applied. This then starts to build up a much more realistic cost for maintaining a bowling green for a year.

Once this table has been completed it is a good idea to convert it into a chart to put the figures into a more easily understood visual perspective.