Introduction

Labour (or workload) profiling is a useful tool that can be used to assist in the effective management of a facility.

Two types of information are needed to complete a profile.

- The estimated time it typically takes to carry out a task, and

- An estimate of how many times the task will be needed over a year to ensure the desired standards are achieved.

Typical times will vary from one operator to another, for example, especially where ride-on/tractor mounted or pedestrian machines are being used. The time may include how long it takes to clean off a machine as well as resetting it for the next time it is used.

This needs to be carefully considered if a comparison is to be made with a similar facility.

The make-up of the times will depend upon individual requirements, however, it is important to try and provide an overall picture that is fairly comprehensive otherwise the maximum benefit will not be gained from this management tool.

The estimated number of times a task is needed will depend upon the overall quality required, usage levels and patterns of use, as well as the prevailing weather and soil conditions. With past diary records a fairly accurate summary can usually be achieved, however, with the vagaries of the weather and actual usage the anticipated monthly figure will no doubt vary from the planned estimate.

The important point to remember is that this tool is only an aid for forecasting workload and should be adjusted as the year progresses to reflect changes in the weather, as well as the quality of the playing surface produced. More or less work may be needed than was originally anticipated: This is to be expected.

This tool should be used as a working document that is continually updated. Experienced groundstaff will be able to forecast to a high level of accuracy.

By planning ahead a number of benefits can be achieved:

- bottle necks in workload (work 'Peaks') can be immediately identified,

- action can be taken to reduce or eliminate these 'Peaks',

- seasonal / contract staff may be employed,

- work may be rescheduled for other times,

- holidays can be planned to minimise impact on the maintenance work (ideally taking some of these when there are work 'Troughs'),

- staff costs can be more accurately budgeted for,

- cash flow can also be determined.

Football Pitch Profile

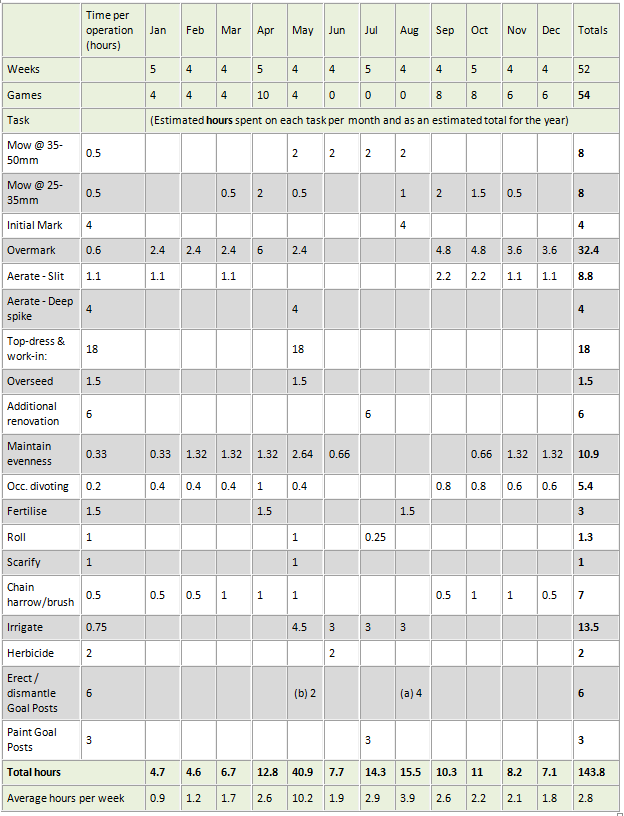

If we look at the maintenance for a football pitch we can plot in the relevant estimates. The following table has used adjusted maintenance figures from the Football Pitch Maintenance Calendar document.

In this example, we are looking at the following:

- a 'Basic' level of Performance Quality Standard,

- pipe drained pitch with on a loamy soil,

- usage is planned as 54 adult games for the season,

- the carrying capacity has been estimated as 60 adult games,

- an irrigation connection point is available, to which a travelling sprinkler can be attached,

- frequency and quantity of rainfall have been arbitrarily taken into account for this hypothetical site.

(Please note that the estimated times are only used to illustrate how labour profiling works. Groundstaff will need to put in their own particular figure. However, many of the times given will be fairly representative of a typical time to undertake the stated task on a football pitch).

Download a word version so you can edit it to suit your own requirements

Profile Operations

Aeration

Due to local conditions, it may be inappropriate to use an aerator over the autumn / winter period. A more effective approach may be to vertidrain in the early autumn and then again at renovation time in May.

Light Rolling

This may not be required for this particular facility. Much will depend upon if the renovated areas have already been firmed within the course of the renovation itself. Light rolling has also been identified in July to firm up the anticipated additional renovation work.

Scarification

It may be appropriate just to turn chain harrow tines to point downwards to undertake an appropriate operation, especially for a 'Basic' level of pitch.

Mowing

This will need to take place when leaf growth is slow due to warm dry conditions as grass flower stalks will need to be controlled to prevent the grass from setting seed, which would result in a thinning of the grass sward.

Additional renovation

This is provisionally included as typically some areas do not establish as well as expected. This could be expected where no artificial irrigation is available and can also result from unexpected casual or unauthorised use of the football pitch, especially if it is located on a general open space area.

Line Marking

A full remarking has been included as a precursor for each game.

Irrigation

This will depend upon the prevailing weather conditions, so in effect this figure could be nil. The time stated relates to putting out a sprinkler, moving it as required and then storing it away. It is not the time actually spent irrigating the pitch.

The above comments hopefully underline the need to respond to local conditions. Whilst a maintenance calendar can be a useful predictive tool, due to the nature of outdoor facility management there is a significant need to be responsive to events on the ground and take maintenance action accordingly.

Maintain evenness

This will include sanding and forking of worn areas. 20 tonnes of sand would typically be allowed for over the playing season.

Goal Mouths

These may be dug over and deep turfed, particularly if there was a late finish to the season and an early start, or training prior, to a new season.

Maintenance Costs

If a nominal figure of £10 per hour is allowed for staff costs (including administrative overheads*), then it can be readily seen that with the operations detailed in the table, the staff costs of maintaining this football pitch is in the region of at least £1,440.

* Material/equipment/machinery costs are sometimes included in 'overhead' figures. This all depends on how the budget figures are built up.

It should be noted that the following may either be not required, or a lesser amount undertaken, subject to the soil conditions and how well the pitch may be retaining its level of quality:

- Additional renovation: This may not be needed, saving 6 hrs + 0.25hrs rolling in July;

- Irrigation: This could be nil, but let us say it half that estimated turns out to be more typical - saving 6.75 hrs;

- No slit tining is undertaken, however, an additional vertidraining is carried out in September/October, making a net saving of 4.8 hrs;

- A more efficient way, such as using a specialist machine/contractor to apply and work in the sand top-dressing applied during renovation. Estimated saving 10 hours.

These three savings result in 27.8 hours being taken off the profile table, which would now have a total figure of 116 hours, or a labour cost of now £1,160.

This example is used just to show that there is a certain amount of variability possible when trying to provide a typical maintenance figure for a football pitch.

Add to this some material costs of £3,000 (50% being for sand) per annum and a maintenance figure of £4,160 is now arrived at.

Additional figures may be needed for the cost of machinery and equipment and the relevant repayment costs, or whatever financing costs applied. (Again these latter two points of materials and machinery/equipment will depend on if these costs are already reflected in the overhead costs).

This then starts to build up a much more realistic cost for maintaining a football pitch for a year.

Once this table has been completed it is a good idea to convert it into a chart to put the figures into a more easily understood visual perspective.

Conclusion

Labour (or workload) profiling is a useful predictive tool that is then adjusted in response to actual conditions 'on the ground' as the season progresses.